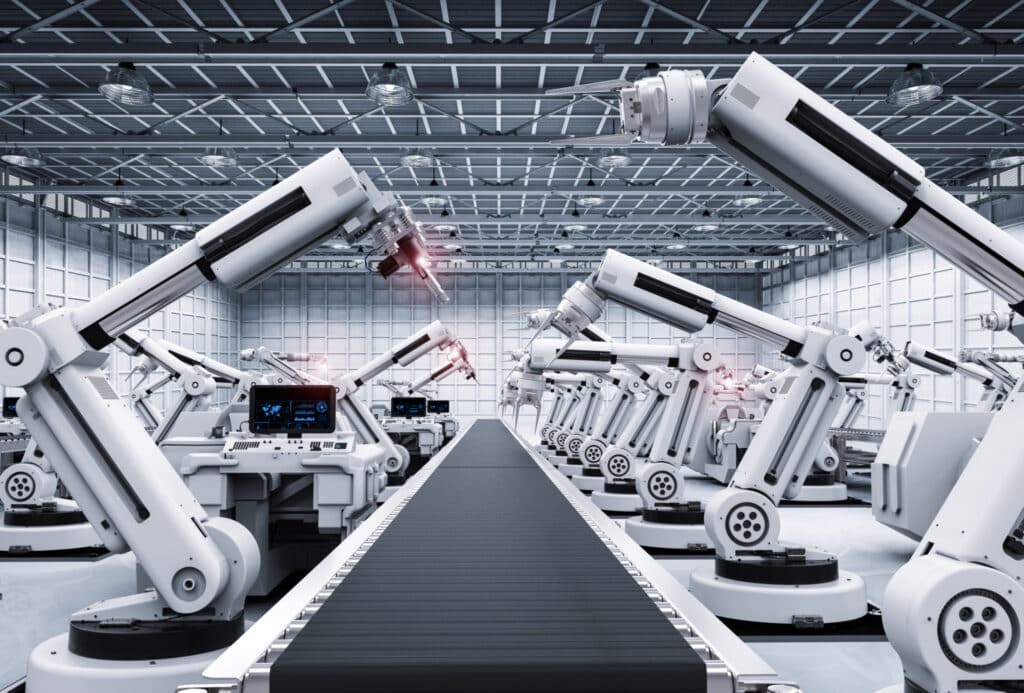

In this article, we explore the fascinating world of AI in industrial automation and how it is revolutionizing the concept of smart factories and manufacturing. From streamlining production processes to improving efficiency and productivity, AI is playing a key role in reshaping the future of the manufacturing industry. Join us on this journey as we discover the innovative applications and benefits of AI in transforming traditional factories into intelligent, interconnected systems.

How AI is Transforming the Manufacturing Industry

Overview of AI in Manufacturing

Artificial Intelligence (AI) is revolutionizing the manufacturing industry by offering new possibilities for efficiency, productivity, and innovation. AI is a field of computer science that enables machines to imitate human intelligence and perform tasks that typically require human thinking. In the context of manufacturing, AI can be applied to various processes, such as industrial automation, predictive maintenance, quality control, demand forecasting, and supply chain optimization. By harnessing the power of AI, manufacturers can enhance their operations, reduce costs, improve product quality, and stay competitive in a rapidly evolving market.

Benefits of AI in Manufacturing

The integration of AI into the manufacturing industry brings numerous benefits and advantages. Firstly, AI technologies enable the automation of tedious and repetitive tasks, freeing up human workers to focus on more complex and value-added activities. This leads to increased efficiency and productivity within the manufacturing processes. AI also facilitates real-time and data-driven decision-making, as it can process and analyze large volumes of information more quickly and accurately than humans. As a result, manufacturers can optimize their operations and make agile adjustments based on real-time insights to meet customer demands and market fluctuations. Furthermore, AI can enhance product quality and defect detection by using computer vision and machine learning algorithms to identify and correct errors during the manufacturing process. With AI, manufacturers can ensure that each product meets the highest standards and reduce the risk of defective products reaching the market.

Challenges in Implementing AI in Manufacturing

While the benefits of AI in manufacturing are immense, there are also several challenges associated with its implementation. One of the primary challenges is the cost of implementing AI technologies and integrating them into existing manufacturing systems. The initial investment required for AI infrastructure, software, and training can be substantial, and many manufacturers may struggle to justify the expenses. Additionally, there may be resistance from the workforce due to concerns about job displacement. To address this challenge, it is crucial for manufacturers to prioritize employee training and education, highlighting the opportunities that AI brings for upskilling and focusing on more complex and creative tasks. Lastly, data security and privacy are paramount concerns when implementing AI in manufacturing. As AI relies on vast amounts of data, it is essential to establish robust cybersecurity measures and comply with relevant data protection regulations to safeguard sensitive information.

Use Cases of AI in Manufacturing

AI has a wide range of applications in the manufacturing industry. Here are some prominent use cases:

Robotics and Autonomous Systems

AI enables the development and deployment of robots and autonomous systems in manufacturing processes. Robots can perform tasks with precision, speed, and consistency, improving overall productivity. Autonomous systems can be used for material handling, assembly, packaging, and even complex tasks requiring decision-making capabilities.

Predictive Maintenance and Equipment Health Monitoring

By utilizing AI techniques, manufacturers can implement predictive maintenance strategies to monitor the health and performance of equipment. Sensors and predictive analytics algorithms can detect anomalies and predict potential failures, allowing manufacturers to schedule maintenance activities proactively. This approach minimizes costly unplanned downtime and optimizes maintenance resources.

Quality Control and Defect Detection

AI-powered computer vision systems can analyze images and videos in real-time to detect defects and anomalies in products. By leveraging machine learning algorithms, manufacturers can train systems to identify and categorize defects accurately, enabling early detection and immediate corrective actions. This improves product quality and reduces waste.

Demand Forecasting

AI models can analyze historical data, market trends, and other relevant variables to forecast demand accurately. Manufacturers can use this information to optimize production and inventory levels, reduce stockouts, and meet customer demands more effectively. Demand forecasting also aids in avoiding overproduction and minimizing excess inventory, resulting in cost savings.

Supply Chain Optimization

AI enables manufacturers to optimize their supply chain operations by automating and streamlining various processes. It includes inventory management and optimization to ensure sufficient stock levels without excessive stockouts or surplus, as well as route planning and logistics optimization to minimize transportation costs and enhance delivery efficiency. AI can analyze complex data sets and make recommendations to optimize the supply chain in real-time, adapting to market fluctuations.

AI Applications in Industrial Automation

Robotics and Autonomous Systems

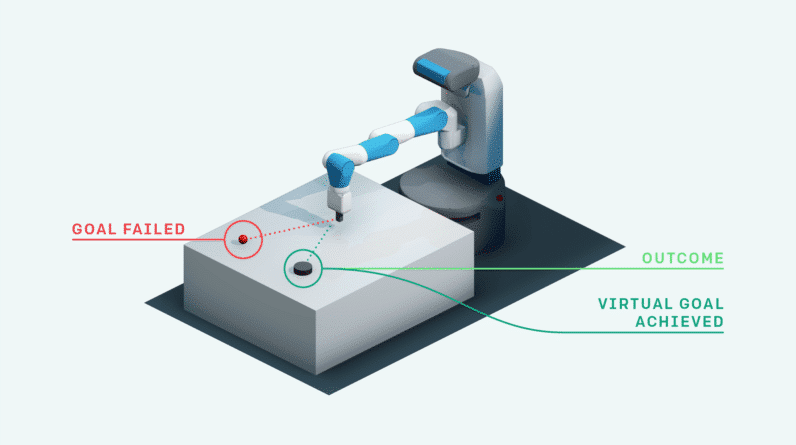

Robotics and autonomous systems are at the forefront of AI applications in industrial automation. These systems involve the use of robots and machines capable of performing tasks autonomously or in collaboration with human workers. The integration of AI algorithms and technologies enables these systems to have advanced sensing capabilities, decision-making abilities, and adaptability to dynamic environments.

Introduction to Robotics and Autonomous Systems

Robotics and autonomous systems have transformed traditional manufacturing processes. These machines can be used in material handling, assembly, welding, painting, and other repetitive tasks that were previously performed by human workers. Automation of these tasks allows for increased efficiency, productivity, and accuracy in manufacturing operations.

Advantages of Robotic Automation

Robotic automation offers numerous advantages in manufacturing. Firstly, robots can perform tasks that are monotonous, dangerous, or physically demanding for human workers. This reduces the risk of occupational hazards and enhances worker safety on the shop floor. Secondly, robots can work continuously without breaks and at a high speed, leading to increased production rates. Additionally, robots can consistently perform tasks with high precision, ensuring product quality and reducing variability.

Collaborative Robots (Cobots)

Collaborative robots, also known as cobots, are designed to work alongside human workers, collaborating and assisting them in various manufacturing tasks. Unlike traditional industrial robots, cobots are equipped with advanced sensors and AI capabilities, allowing them to interact safely with human workers and adapt to dynamic environments. Cobots can be employed in tasks such as machine tending, bin picking, and assembly, enhancing productivity and efficiency while maintaining a safe working environment.

AI in Robot Programming

AI plays a crucial role in simplifying and accelerating the programming of robots. Traditional robot programming often requires highly specialized skills and extensive programming knowledge. However, with AI techniques such as machine learning and natural language processing, programming robots becomes more intuitive and accessible. Manufacturers can utilize graphical user interfaces, drag-and-drop programming, and even voice commands to program robots, reducing the learning curve and enabling non-experts to use robots effectively.

Robotic Process Automation (RPA)

Robotic Process Automation (RPA) involves automating repetitive and rule-based tasks performed by human workers. RPA utilizes AI capabilities to mimic human interactions with digital systems and software, making it possible to automate tasks such as data entry, order processing, and report generation. By implementing RPA, manufacturers can enhance operational efficiency, reduce errors, and free up human workers to focus on more complex and value-added activities.

Predictive Maintenance and Equipment Health Monitoring

Predictive maintenance and equipment health monitoring leverage AI technologies to monitor the condition and performance of machinery and equipment in real-time. By analyzing sensor data and utilizing predictive analytics algorithms, manufacturers can identify potential equipment failures before they occur, allowing for proactive maintenance and minimizing unplanned downtime.

Importance of Predictive Maintenance in Manufacturing

Predictive maintenance is a proactive maintenance strategy that aims to detect and address equipment failures before they lead to costly unplanned downtime. Traditional maintenance approaches, such as reactive maintenance or scheduled preventative maintenance, can be inefficient and result in production disruptions or unnecessary maintenance activities. Predictive maintenance optimizes maintenance resources, reduces maintenance costs, and improves overall equipment effectiveness (OEE).

Condition Monitoring and Predictive Analytics

Condition monitoring involves the continuous measurement and analysis of various parameters, such as temperature, vibration, pressure, and current, to evaluate the health of equipment. AI techniques, such as machine learning and data analytics, enable manufacturers to process and analyze large volumes of sensor data in real-time, detecting deviations from normal operating conditions. By applying predictive analytics algorithms to the collected data, manufacturers can predict equipment failures and take proactive actions to prevent them.

AI Techniques for Predictive Maintenance

AI techniques, such as machine learning, are instrumental in predictive maintenance. By training machine learning models on historical sensor data and maintenance records, manufacturers can build predictive models for specific equipment. These models can then be used to forecast the remaining useful life of equipment and predict potential failure events. By combining these predictions with real-time sensor data, manufacturers can optimize maintenance activities, schedule equipment downtime strategically, and minimize the impact on production.

Real-time Equipment Health Monitoring

Real-time equipment health monitoring allows manufacturers to monitor the condition and performance of machinery in real-time. Sensors attached to equipment collect data on various parameters, such as temperature, vibration, and power consumption. This data is continuously analyzed using AI algorithms to detect anomalies, deviations, or patterns that indicate impending failure. Real-time alerts and notifications can then be generated to alert maintenance personnel to potential issues so that they can take immediate action.

Quality Control and Defect Detection

Quality control is a critical aspect of manufacturing to ensure that products meet the required specifications and standards. AI technologies, such as computer vision and machine learning, offer powerful tools for defect detection and automated inspection, improving product quality and minimizing the risk of defective products reaching the market.

Importance of Quality Control in Manufacturing

Maintaining high-quality standards is crucial for manufacturers to uphold their reputation and meet customer expectations. Quality control processes involve inspecting products at various stages of production to identify and address any defects or deviations from specifications. AI-based quality control systems can provide quick and accurate defect detection, leading to improved product quality, reduced waste, and increased customer satisfaction.

Computer Vision and Machine Learning for Defect Detection

Computer vision, a subfield of AI, focuses on training machines to understand and interpret visual information. In the context of quality control, computer vision algorithms are applied to images or videos of products to detect defects or anomalies. Machine learning techniques enable these algorithms to learn from labeled training data and develop the ability to identify specific defects accurately.

Automated Inspection Systems

AI-powered automated inspection systems can process large volumes of visual data quickly and accurately. These systems can detect defects such as scratches, dents, color variations, or missing components in real-time. By replacing manual inspection tasks with automated systems, manufacturers can improve inspection accuracy, reduce human error, and increase inspection throughput rates.

Real-time Quality Monitoring

Real-time quality monitoring allows manufacturers to monitor product quality during the manufacturing process continuously. AI algorithms and sensors can analyze relevant metrics and parameters, such as temperature, pressure, or chemical composition, to ensure that products are being manufactured within the desired specifications. Real-time alerts can be generated when deviations from the defined quality parameters occur, enabling immediate corrective actions.

Stay tuned for the next sections of the comprehensive article!