In today’s rapidly evolving world of supply chain and logistics, the integration of artificial intelligence (AI) is proving to be transformative. By harnessing the power of AI, businesses are able to optimize operations and improve the efficiency of their delivery processes. From enhancing demand forecasting to streamlining warehouse management, AI is revolutionizing the way goods are transported and distributed. In this article, we will explore the various ways in which AI is being implemented in the supply chain and logistics industry, and the impact it is having on businesses worldwide.

Benefits of AI in Supply Chain and Logistics

Improved Efficiency

One of the key benefits of using AI in supply chain and logistics is improved efficiency. AI-powered algorithms can analyze large amounts of data and optimize various processes within the supply chain, such as inventory management, route planning, and demand forecasting. By automating routine tasks and providing real-time insights, AI enables businesses to streamline their operations, reduce manual errors, and improve overall efficiency.

Enhanced Accuracy

AI technology can significantly enhance accuracy in supply chain and logistics operations. Machine learning algorithms are capable of analyzing vast amounts of historical data to identify patterns and trends that humans may overlook. This enables businesses to make more accurate demand forecasts, identify potential bottlenecks or risks, and optimize inventory levels. By minimizing errors and improving accuracy, organizations can reduce costly mistakes and improve customer satisfaction.

Reduced Costs

Another significant advantage of AI in supply chain and logistics is the potential for reducing costs. By automating processes and optimizing operations, businesses can minimize wastage, improve resource allocation, and reduce unnecessary expenses. AI-driven demand forecasting, for example, helps organizations avoid overstocking or stockouts, which can lead to costly repercussions. Additionally, efficient route planning and optimization algorithms can minimize fuel usage and transportation costs. By implementing AI technologies, businesses can identify cost-saving opportunities and improve their bottom line.

Faster Decision Making

AI enables faster decision making in supply chain and logistics by providing real-time insights and predictions. Through machine learning algorithms and predictive models, businesses can quickly analyze complex data sets and make data-driven decisions. For example, real-time traffic analysis and delivery time estimation help logistics personnel optimize routes and make informed decisions about resource allocation. With AI-powered tools, organizations can respond swiftly to changing market conditions, unexpected disruptions, and customer demands, leading to improved operational efficiency and customer satisfaction.

AI-Driven Demand Forecasting

Machine Learning Algorithms

At the core of AI-driven demand forecasting are machine learning algorithms. These algorithms analyze historical data, including past sales, market conditions, and customer behavior, to identify patterns and trends. By learning from this data, the algorithms can predict future demand accurately and help organizations optimize their inventory levels, production schedules, and resource allocation. Machine learning algorithms continuously improve their accuracy as they learn from new data, allowing businesses to make more informed decisions about demand forecasting.

Data Analysis and Predictive Models

AI-driven demand forecasting relies on advanced data analysis techniques and predictive models. Large volumes of data, including sales data, market trends, customer preferences, and external factors, are collected and analyzed to generate accurate forecasts. Through statistical analysis and predictive modeling, organizations can estimate future demand patterns to support decision making. AI-enabled tools can process and analyze this data much faster and more accurately than humans, allowing businesses to respond quickly to changes in demand and gain a competitive advantage.

Real-time Demand Tracking

Real-time demand tracking is another crucial aspect of AI in supply chain and logistics. By leveraging real-time data from various sources, such as point-of-sale systems, online platforms, and social media, businesses can gain immediate insights into customer demand. AI algorithms can process this data in real-time, allowing organizations to adjust their inventory levels, production schedules, and distribution strategies to meet customer needs effectively. Real-time demand tracking enables businesses to be more agile and responsive, reducing lead times, minimizing stockouts, and improving overall customer satisfaction.

Optimizing Inventory Management with AI

Demand-Sensing Technologies

AI-powered demand-sensing technologies play a vital role in optimizing inventory management. These technologies use advanced analytics and machine learning algorithms to capture and analyze real-time demand signals from various sources. By capturing and interpreting data from social media, online platforms, and other customer touchpoints, businesses can gain valuable insights into changing customer preferences and demand patterns. This enables organizations to adjust their inventory levels and production schedules accordingly, minimizing stockouts and excess inventory.

Automated Replenishment

AI enables automated replenishment by analyzing demand patterns and automatically triggering reorder points. By continuously monitoring inventory levels, sales data, and demand forecasts, AI-powered systems can generate purchase orders or production requests when stock levels fall below a certain threshold. Automated replenishment eliminates the need for manual intervention, reduces the risk of stockouts, and ensures optimal inventory levels. This not only improves operational efficiency but also enhances customer satisfaction by ensuring products are always available.

Dynamic Warehouse Management

AI can revolutionize warehouse management by introducing dynamic and real-time optimization techniques. With AI-enabled systems, businesses can automate various processes within the warehouse, such as inventory placement, picking optimization, and bin replenishment. By leveraging real-time data, including order volumes, order priorities, and warehouse capacity, AI systems can dynamically allocate resources, optimize picking routes, and minimize travel time. This streamlines warehouse operations, reduces labor costs, and improves overall efficiency and productivity.

Efficient Route Planning and Optimization

Real-Time Traffic Analysis

AI in supply chain and logistics allows for real-time traffic analysis, which is crucial for optimizing route planning. By integrating AI with live traffic data and GPS information, businesses can monitor traffic conditions and identify the most efficient routes in real-time. AI algorithms can analyze historical traffic patterns and predict potential congestion or delays, enabling organizations to proactively plan alternative routes and minimize delivery time. Real-time traffic analysis ensures timely deliveries, reduces transportation costs, and enhances customer satisfaction.

Delivery Time Estimation

Delivery time estimation is significantly improved with AI technologies. AI algorithms can process various factors such as distance, traffic conditions, weather, and order volumes to accurately estimate delivery times. By considering these variables, businesses can provide customers with accurate delivery time frames, enhancing transparency and reliability. Improved delivery time estimation also allows organizations to proactively manage customer expectations, reducing uncertainty and improving overall customer experience.

Optimal Routing Algorithms

AI enables the use of optimal routing algorithms for efficient delivery planning. These algorithms consider multiple variables such as delivery locations, order volumes, traffic conditions, and vehicle capacities to generate the most optimized routes. By minimizing travel distance, reducing fuel consumption, and improving resource utilization, optimal routing algorithms can help businesses optimize their logistics operations. AI-powered route optimization enables organizations to save time and costs, improve delivery efficiency, and enhance overall customer satisfaction.

Enhancing Warehouse Operations with AI

Automated Sorting and Picking

AI can automate and optimize the sorting and picking processes within warehouses. By leveraging machine learning algorithms and computer vision technology, AI systems can quickly and accurately identify items, sort them according to predefined criteria, and optimize picking routes. Automated sorting and picking systems not only increase efficiency but also reduce errors and labor costs. Additionally, AI-powered systems can continuously learn and improve their performance, leading to further optimization and cost reduction.

Inventory Tracking and Management

AI plays a crucial role in inventory tracking and management by providing real-time visibility into inventory levels and locations. By integrating AI with IoT devices, businesses can track individual items, monitor stock levels, and receive automatic notifications for restocking. AI-powered inventory tracking systems streamline the process of inventory counting and reconciliation, reducing manual errors and improving accuracy. Real-time visibility into inventory levels enables businesses to respond quickly to changes in demand, minimize stockouts, and enhance overall operational efficiency.

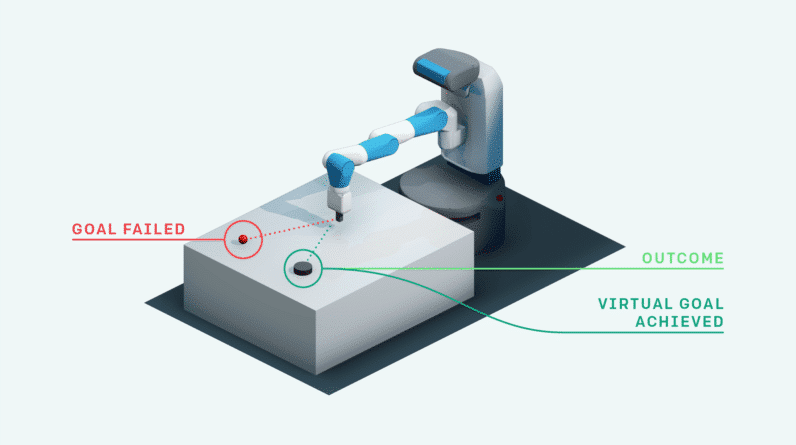

Intelligent Robotics

Intelligent robotics, powered by AI, are revolutionizing warehouse operations. AI-powered robots can navigate autonomously, efficiently and safely perform tasks such as picking, packing, and inventory management. These robots are equipped with advanced sensors and machine learning algorithms that enable them to adapt to changing environments and collaborate with human workers. By deploying intelligent robotics, businesses can increase productivity, reduce manual labor, and optimize overall warehouse operations.

AI-Powered Supply Chain Visibility

End-to-End Tracking and Tracing

AI enables end-to-end tracking and tracing capabilities within the supply chain. By integrating AI with IoT devices and sensors, businesses can track and monitor products at every stage, from manufacturing to delivery. Real-time data collection and analysis allow organizations to have full visibility into the supply chain, identifying potential bottlenecks, delays, or disruptions. This level of visibility enhances supply chain transparency, improves demand forecasting, and enables more effective risk management.

Real-Time Monitoring

AI-powered real-time monitoring provides businesses with up-to-the-minute insights into supply chain operations. By collecting and analyzing data from various sources, such as IoT devices, sensors, and ERP systems, AI systems can identify anomalies, deviations, or potential issues. Real-time monitoring enables organizations to proactively address supply chain disruptions, minimize risks, and ensure operational continuity. Timely insights provided by AI-powered monitoring tools allow businesses to make data-driven decisions and respond swiftly to emerging challenges.

Supply Chain Analytics

AI-driven supply chain analytics offers organizations deeper insights into their operations and performance. By analyzing large volumes of data, including sales data, transportation costs, inventory levels, and customer feedback, AI algorithms can identify patterns, trends, and potential areas for improvement. Supply chain analytics powered by AI enables businesses to optimize processes, identify cost-saving opportunities, and enhance overall operational efficiency. By leveraging these insights, organizations can make proactive changes, implement continuous improvements, and gain a competitive advantage.

Predictive Maintenance and Quality Control

Continuous Equipment Monitoring

AI enables continuous equipment monitoring, which allows organizations to detect potential faults or failures before they occur. By integrating AI with IoT sensors and equipment data, businesses can collect real-time information about equipment performance, temperature, and other variables. AI algorithms can analyze this data to identify patterns and anomalies that may indicate impending breakdowns or maintenance needs. Continuous equipment monitoring helps organizations prevent costly downtime, improve maintenance planning, and optimize overall equipment effectiveness.

Anomaly Detection

Anomaly detection is a vital component of predictive maintenance and quality control. AI algorithms can analyze historical data about equipment performance, maintenance records, and other variables to establish baselines and identify deviations from normal behavior. By continuously monitoring equipment performance and comparing it to established norms, AI-powered systems can alert organizations to potential issues or anomalies. Early detection of anomalies allows businesses to take timely corrective actions, minimize disruptions, and ensure product quality and customer satisfaction.

Early Warning Systems

AI enables the development of early warning systems that alert organizations to potential quality issues or supply chain disruptions. By analyzing real-time data from multiple sources, such as production lines, transportation routes, and customer feedback, AI algorithms can identify signals indicating potential problems. Early warning systems help businesses take proactive measures to prevent quality issues, minimize risks, and ensure smooth supply chain operations. AI-powered early warning systems enable organizations to mitigate potential impacts and maintain a high level of quality and customer satisfaction.

Improved Last-Mile Delivery Experience

Delivery Drones and Robotics

AI-powered delivery drones and robotics are transforming the last-mile delivery experience. By leveraging AI algorithms and advanced navigation systems, businesses can automate and optimize the delivery process. Delivery drones and intelligent robots can navigate through traffic, avoid obstacles, and deliver packages directly to customers, even in congested urban areas. AI-enabled last-mile delivery systems reduce delivery times, lower transportation costs, and enhance overall customer satisfaction by providing faster and more convenient delivery options.

Delivery Time Optimization

AI technology is instrumental in optimizing delivery times in the last-mile delivery process. By analyzing data such as delivery addresses, traffic conditions, and order volumes, AI algorithms can generate optimized delivery schedules and routes. This allows businesses to minimize delivery time and increase the efficiency of their last-mile operations. Delivery time optimization also enables organizations to provide accurate and reliable delivery time estimates to customers, improving customer experience and satisfaction.

Enhanced Customer Communication

AI empowers businesses to enhance customer communication and engagement throughout the last-mile delivery process. By integrating AI with customer-facing platforms, such as mobile apps or chatbots, organizations can provide real-time updates, delivery notifications, and interactive communication channels. AI-powered chatbots can handle customer inquiries and provide personalized assistance, improving the overall customer experience. Enhanced customer communication not only increases customer satisfaction but also helps businesses build stronger customer relationships and foster loyalty.

Risk Management and Mitigation

Supply Chain Disruption Forecasting

AI technology enables supply chain disruption forecasting, helping businesses minimize risks and mitigate potential impacts. By analyzing historical data, market trends, and other variables, AI algorithms can identify patterns that may indicate potential disruptions, such as natural disasters, supplier issues, or geopolitical events. Supply chain disruption forecasting allows organizations to proactively develop contingency plans, diversify suppliers, or adjust production schedules to minimize disruptions and maintain business continuity.

Fraud Detection and Prevention

AI plays a crucial role in fraud detection and prevention within the supply chain. Advanced AI algorithms can analyze large volumes of data, including sales transactions, supplier records, and financial information, to identify patterns and anomalies that may indicate fraudulent activities. By continuously monitoring these data sources, AI systems can detect and alert organizations to potential fraud risks. Fraud detection and prevention powered by AI enable businesses to protect their supply chains, minimize financial losses, and maintain integrity and trust with customers and partners.

Real-Time Crisis Response

AI technology enables real-time crisis response capabilities within the supply chain. By integrating AI with various data sources, including IoT devices, social media, and news feeds, businesses can monitor and analyze information in real-time during crises. AI algorithms can identify relevant signals, assess their impact, and provide organizations with timely insights and recommendations. Real-time crisis response powered by AI enables businesses to make quick and informed decisions, implement necessary measures, and mitigate potential crises effectively.

AI Adoption Challenges in Supply Chain

Data Integration and Compatibility

One of the key challenges in adopting AI in supply chain and logistics is data integration and compatibility. Organizations often have multiple systems and databases, each with its own data format and structure. Integrating these different data sources and making them compatible with AI algorithms can be a complex and time-consuming process. However, overcoming this challenge is crucial to enable data-driven decision making and realize the full potential of AI in supply chain and logistics.

Cost of Implementation

Implementing AI technologies in supply chain and logistics can be a significant investment for organizations. AI requires sophisticated infrastructure, including powerful computing resources and advanced analytics tools. Additionally, organizations may need to allocate resources for data collection, integration, and employee training. While the benefits of AI in supply chain and logistics are substantial, the upfront costs can be a barrier for some businesses. Recognizing the long-term advantages and return on investment is essential to overcome this challenge and embrace AI adoption.

Employee Training and Acceptance

AI adoption in supply chain and logistics often requires training employees to work alongside AI-powered systems. Organizations need to provide proper training and support to employees to ensure they can effectively collaborate with AI technologies and utilize them to their full potential. Additionally, organizations need to address any concerns or resistance to AI adoption among employees. Effective change management strategies, transparent communication, and ongoing engagement can help employees embrace AI and understand its role in improving their work processes and outcomes.

In conclusion, AI technology offers numerous benefits in supply chain and logistics, including improved efficiency, enhanced accuracy, reduced costs, and faster decision making. By leveraging AI-driven demand forecasting, optimizing inventory management, and efficient route planning, businesses can streamline their operations and improve customer satisfaction. AI-powered warehouse operations, supply chain visibility, and predictive maintenance enable organizations to optimize processes, mitigate risks, and enhance overall performance. However, organizations must overcome challenges such as data integration, cost of implementation, and employee training to fully unlock the potential of AI in supply chain and logistics. With proper planning and strategic implementation, AI can revolutionize the industry and drive significant improvements in operations and delivery.